Uncover the Hidden Control Type Behind Training, Inspection, and Housekeeping: A Deep Dive

Modern businesses thrive on efficiency, safety, and consistent quality. Achieving these goals often hinges on a trifecta of critical operational elements: training, inspection, and housekeeping. While seemingly distinct, these practices are interconnected by a crucial, often overlooked, control type that dictates their effectiveness. Understanding this hidden control type is vital for optimizing your operations and achieving peak performance. Let’s delve into the specifics.

The Unseen Hand: Process Control

The hidden control type connecting training, inspection, and housekeeping is process control. Process control provides the framework for these activities, ensuring they are performed consistently, accurately, and effectively. It’s the backbone that dictates how these activities are executed, not just that they are executed.

Think of it this way:

- Training: Process control standardizes the training curriculum, delivery methods, assessment criteria, and documentation.

- Inspection: Process control defines inspection checklists, frequency, reporting procedures, and corrective action protocols.

- Housekeeping: Process control establishes cleaning schedules, waste disposal protocols, storage guidelines, and safety procedures.

Without robust process control, these activities become sporadic, inconsistent, and ultimately, less impactful.

Process Control’s Impact on Training

Effective training isn’t just about delivering information; it’s about ensuring the information is understood, retained, and applied consistently. Process control plays a vital role in achieving this by:

- Defining standardized curricula: Ensures all trainees receive the same essential information.

- Establishing clear learning objectives: Sets expectations and provides measurable outcomes.

- Implementing consistent training methods: Includes lectures, hands-on practice, and simulations.

- Utilizing assessment tools: Tests knowledge and understanding.

- Tracking training completion and effectiveness: Monitors progress and identifies areas for improvement.

- Providing refresher training protocols: Ensures knowledge is maintained over time.

By applying process control to training, organizations can minimize errors, improve employee performance, and enhance overall safety.

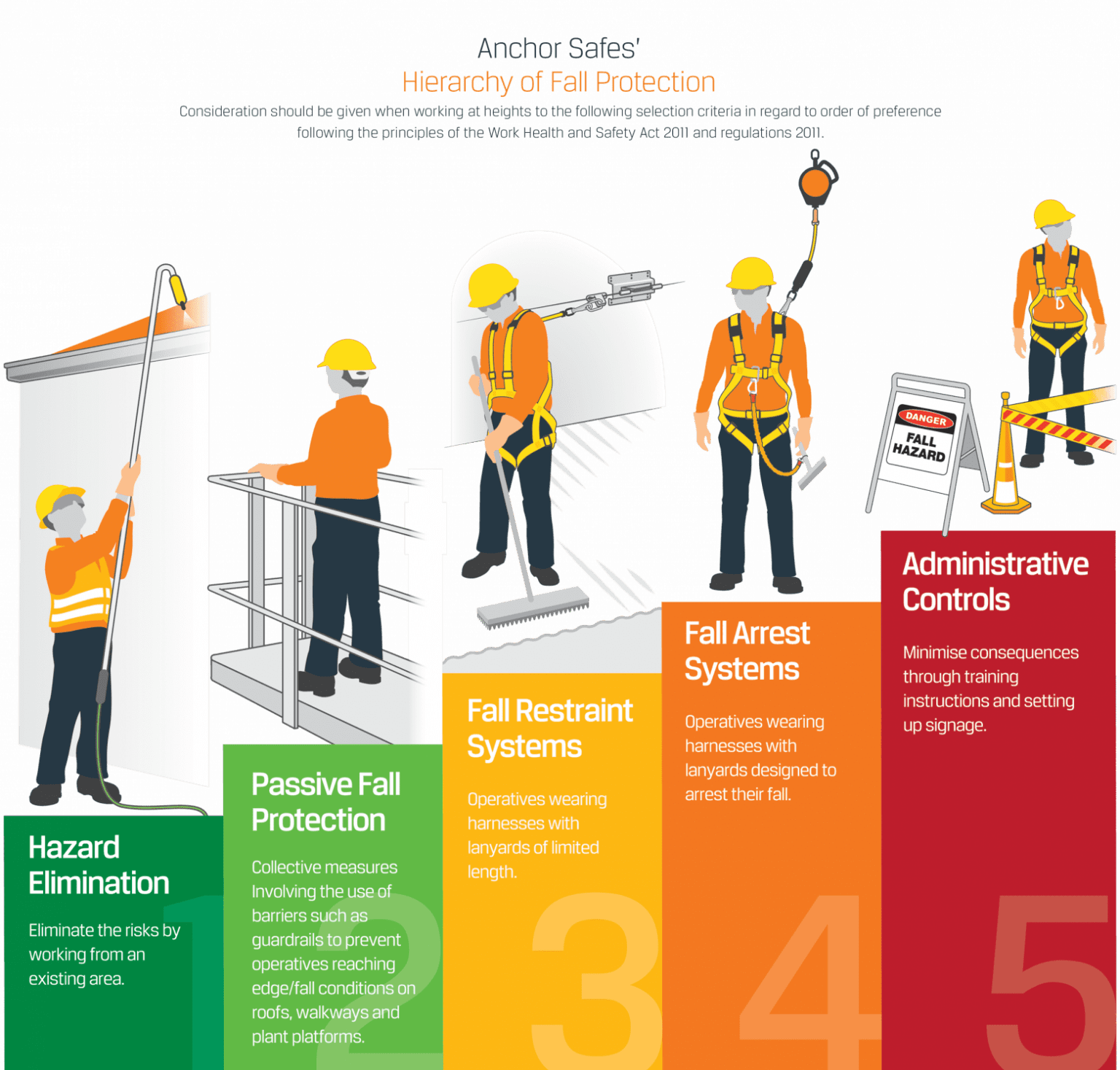

How Process Control Enhances Inspection Procedures

Inspections are crucial for identifying potential hazards, ensuring compliance, and maintaining quality. Process control streamlines this process by:

- Creating standardized checklists: Ensures all relevant aspects are evaluated.

- Defining inspection frequency: Determines the appropriate intervals for inspections.

- Establishing clear reporting protocols: Facilitates efficient communication of findings.

- Implementing corrective action procedures: Outlines steps to address identified issues.

- Tracking inspection results and trends: Provides valuable data for continuous improvement.

- Assigning responsibilities: Clarifies who is accountable for inspections and follow-up actions.

Robust process control in inspection procedures minimizes risks, ensures regulatory compliance, and supports a culture of safety and quality.

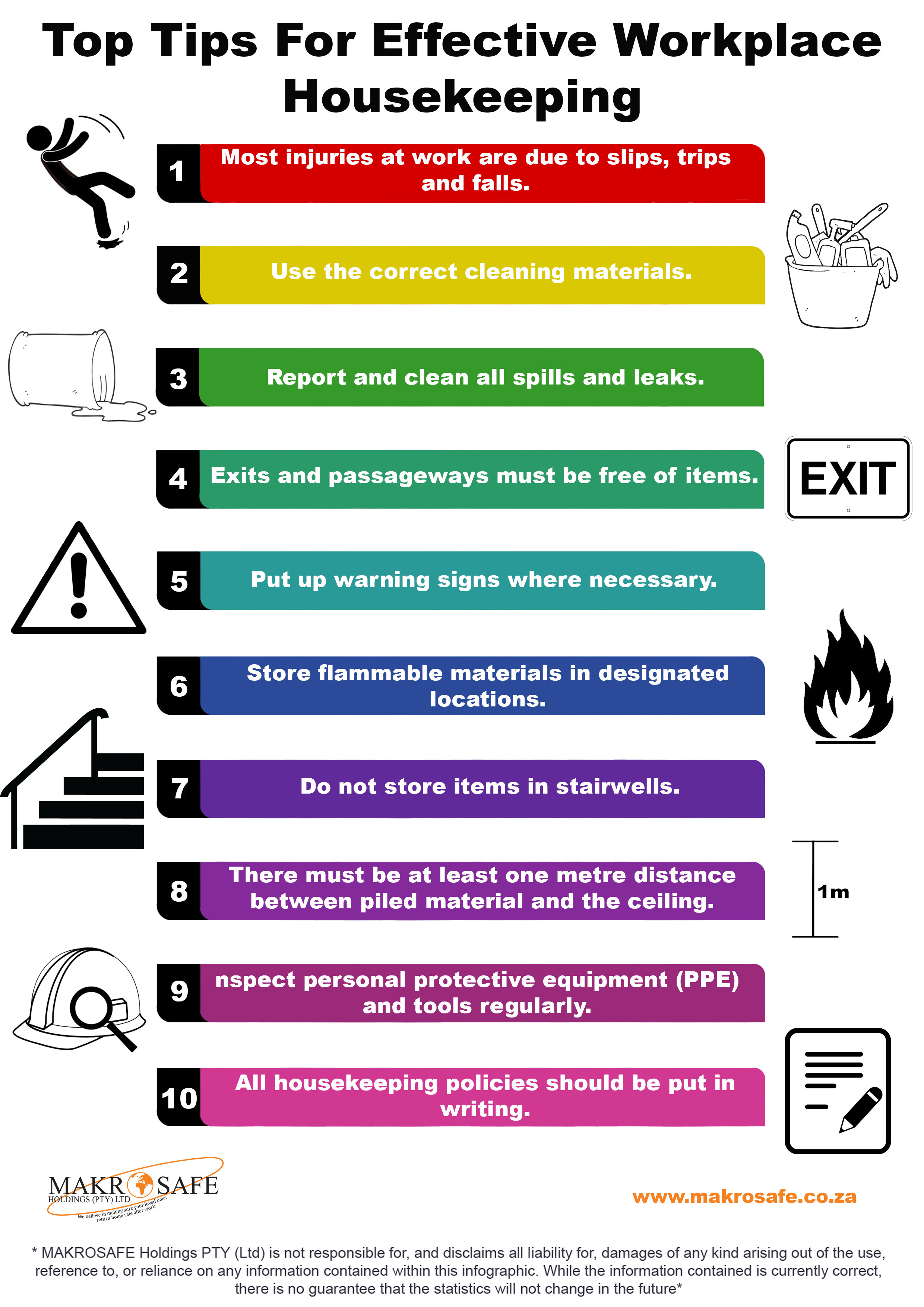

The Role of Process Control in Maintaining Housekeeping Standards

Maintaining a clean, organized, and safe work environment is essential for productivity, safety, and employee morale. Process control provides the structure for:

- Developing cleaning schedules: Specifies when and how often cleaning tasks are performed.

- Defining waste disposal protocols: Ensures proper handling and disposal of waste materials.

- Establishing storage guidelines: Promotes organized storage of materials and equipment.

- Implementing safety procedures: Addresses potential hazards, such as spills and slips.

- Providing tools and equipment: Ensures that employees have the necessary resources to perform their tasks.

- Conducting regular housekeeping inspections: Verifies compliance with established standards.

By implementing process control in housekeeping, organizations can create a safer, more efficient, and more appealing work environment.

Implementing Effective Process Control

Successfully implementing process control requires a systematic approach:

- Identify Critical Processes: Determine which processes within training, inspection, and housekeeping are most critical.

- Document Procedures: Create clear, concise, and easily accessible procedures for each process.

- Provide Training: Train employees on the established procedures and their importance.

- Monitor Performance: Track key metrics to assess the effectiveness of the processes.

- Regularly Review and Update: Continuously review and update procedures to ensure they remain relevant and effective.

- Use Technology: Employ software solutions for streamlined training, inspection, and housekeeping management.

Conclusion: Mastering the Control Type

Process control is the unsung hero of effective training, inspection, and housekeeping. By implementing robust process control measures, organizations can create a safer, more efficient, and more productive work environment. Investing in process control is an investment in your people, your processes, and your bottom line. Prioritizing this hidden control type is key to long-term success and operational excellence.

Frequently Asked Questions (FAQs)

1. What are some examples of process control tools?

Examples include standard operating procedures (SOPs), checklists, flowcharts, training manuals, and software for managing training, inspections, and housekeeping.

2. How do I know if my process control is effective?

Evaluate effectiveness by tracking key performance indicators (KPIs) such as error rates, incident rates, inspection completion rates, and employee satisfaction scores. Continuous improvement is key.

3. What are the benefits of strong process control?

Benefits include reduced errors, improved safety, increased efficiency, enhanced quality, regulatory compliance, and improved employee morale.

4. Can process control be automated?

Yes, many aspects of process control can be automated using software and technology, particularly in areas like training delivery, inspection scheduling, and reporting.

5. How do I get started with process control?

Start by identifying the most critical areas in your training, inspection, and housekeeping processes. Document your current practices, identify gaps, and then develop and implement standardized procedures.